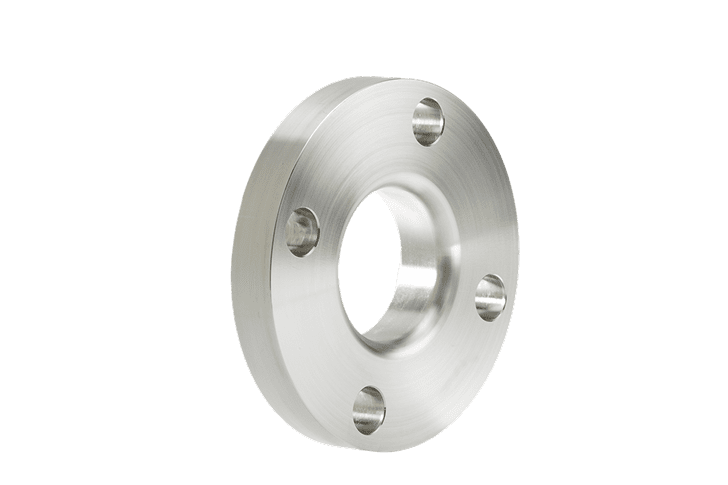

flange

Lap Joint

Flange

Lap Joint

Nearly identical to a slip-on flange, but having a radius at the intersection of the bore and the flange face to accommodate a lap stub end. These flanges slip over the pipe and are not otherwise welded or fastened to it. Bolting pressure is transmitted to the gasket by the pressure of the flange against the back of the pipe lap (stub-end). The face on the stub-end forms the gasket face of the flange. Lap-Joint flanges do not have raised faces and a single connection requires both lap-joint flange and a pipe stub-end. They are best used where sections of piping systems need to be dismantled quickly and easily for inspection or replacement.

Dimensions

- B16.5

- ½” – 24″

- 150# – 2500#

24″ and larger available per customer specifications

Primary Alloys Inventoried

- Hastelloy – C276, B3, C22, C-2000, G-30, 230

- Alloy 20, 200/201, 400, 600, 601, 625, 800HT, 825

- AL6XN (N08367), 904L, 310, 317L, 321, 347

- Duplex Stainless – 2205, 2507, 255

- Titanium – Grades 2, 7, and 12

- Aluminum Grades – 1100, 3003, 6061 and 5083

- Chromes-Moly – F-5, F-9, F-11 and F-22

Other material available upon request

ISO 9001:2015, PED 2014/68/EU, Canadian Registration Numbers (CRN’s: Nuclear and Non-Nuclear), AIS, NCA3800, 10CFR50, 10CFR21, CSA N285.0, CSA B51, NQA-1, EB2678, MIL-I-45208A, DFARS, NACE, EN 10204 3.1

Discuss Your Project

Ready to move forward with your project? Take the next step by requesting a quote or talking directly to our experts about industry-specific needs.